Bisphenol A in Baby Bottles

Bisphenol A (BPA) is used as a monomer in the production of polycarbonate plastic (PC) for various applications. Polycarbonate is typically used for optically transparent applications such as food packaging and also baby bottles. With polycarbonate, a certain migration of the non-polymerised residual monomer can occur from the material over the lifetime of the article or product.

When food or milk is in direct contact with a container manufactured from PC, BPA can migrate into the contents and subsequently can be consumed.

BPA is suspected to negatively affect the nervous system, growth hormones and also baby development. Moreover, even a low amount of BPA can be carcinogenic and also cause immunodeficiency, obesity and diabetes.

Steaming baby bottles for sterilization can accelerate the migration of BPA. In July 2012, the FDA amended its regulations to no longer support the use of BPA-based polycarbonate resins in baby bottles, sippy cups and similar products for babies. Furthermore, Canada, the European Union, China, Malaysia, South Africa and some states of USA have banned the production, use and distribution of these products intended for food applications.

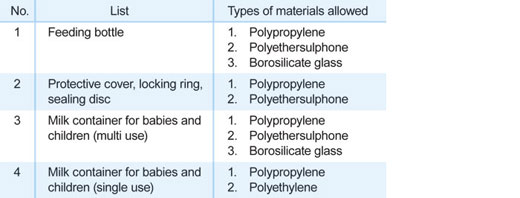

In Thailand, the Ministry of Public Health has reviewed and revised the regulation of materials for baby bottles and on August 1, 2015 announced the following directive:

Types of materials allowed for baby bottles*

* Data from Notification of the Thailand Ministry of Public Health (No. 369) B.E.2558 (2015)

How can we avoid baby bottles with BPA?

We should avoid polycarbonate which is identified by the number 7 in the recycling symbol moulded into the bottom of the product. In the current market, polypropylene baby bottles offer the alternative option due to their thermal resistance, high strength and excellent optics. They are identified by the recycling symbol number 5.

HMC makes sure through supplier audits and questionnaires that we are aware of BPA contained in any raw materials that may be utilized in our PP production process.

If customers would like to check the BPA status of any HMC product used in an application, please download the relevant HMC RAPIDS document or contact HMC’s Regulatory Engineer at regulatory@hmcpolymers.com