Novel PP for Film Capacitors

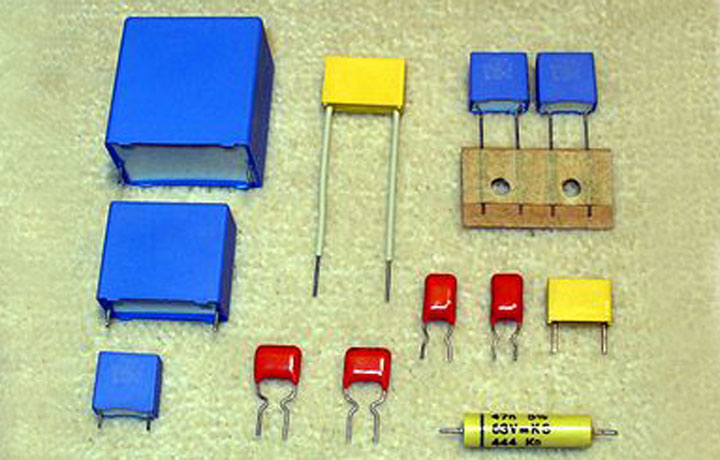

Polypropylene (PP) is the polymer most used as an electrical insulator because it provides high dielectric strength as well as low moisture absorption. In principle, polypropylene is also suitable for film capacitor applications. Film capacitors are electric capacitors in which an insulating plastic film is used as the dielectric. The insulating plastic film can be polyester, polyethylene terephthalate, polycarbonate or polypropylene.

The film capacitor application is particularly sensitive to even small amounts of metallic impurities however, which standard polypropylene may contain, originating from catalyst and co-catalyst residue.

Consequently, commercial polypropylene materials applicable for film capacitors are usually produced with the application of an additional washing step in which catalyst residues are removed.

HMC Polymers has now developed and successfully produced a novel polypropylene grade, Moplen HP6047. This material is produced under optimized production conditions and using a novel Ziegler-Natta catalyst in order to maximize catalyst mileage using Spheripol technology. In addition, the product design and additivation package were optimized in the development process to fulfill the stringent impurities requirements for film capacitors.

HMC Polymers is the first company in the world using Spheripol technology to offer a polypropylene film capacitor grade that does not require a separate costly washing step.

With a novel special properties product designed for Spheripol technology, HMC received the “Bronze” award of “Innovation idea” for “Superior purity Polypropylene resin for film” at the PTT Innovation Awards 2016. HMC is continuously improving its PP product portfolio to ensure customers are at the leading edge of product mechanical and processing capabilities.