Polypropylene (PP)

Polypropylene (PP) is a group of polymer products of the downstream petrochemical industry generated by the propylene polymerisation process with the Ziegler-Natta catalyst. The product lines vary in multiple grades and therefore provide unlimited applications perfectly suiting everyday demands. With this spectrum of applications, HMC Polymers can provide products and solutions to assorted customers’ demands.

A Superior Product Portfolio

Thanks to numerous applications, our PP products yield manufacturing and production of countless consumer goods, fresh-food packaging, construction materials of high sturdiness, auto parts and parts of electrical appliances, durable textiles, healthcare applications, piping, and others.

Combined with the application to substitute other native raw materials such as glasses, woods, metals, and other lower-quality polymers, PP products are in higher and higher demand in all markets.

- Low density (0.9 g/cm3)

- Noise resistance

- Easy moulding

- Numerous applications and moulding option

- Easy colour blending

- Easily modified

- Vapour-resistance and moisture-resistance

- Excellent chemical resistance

- Recyclable

PP comes in various forms, flexible and rigid packaging, and can therefore be applied for a variety of uses in households, garments and textiles, or moulded for sizeable parts for many industries such as auto parts.

PP can be recycled, in line with the trends of packaging and other products. They can be moulded into numerous forms such as for biaxially oriented (BOPP), blown moulding, extrusion blow moulding and injection etc.. Their physical properties can be readily modified by simple chemical and additive reactions to enhance durability and chemical resistance well as insulating capacity.

Homopolymers have an isotactic molecular structure, resulting in higher melting points and excellent strength, excellent scratch resistance, and chemical corrosion resistance, either acidic, basic, or ionic, as well as excellent resistance to environmental stress crack resistance (ESCR), including from contact with alcohol, ester, detergent, and other ionic hydrocarbon compounds.

HOMO PP has a wide range of MFRs and therefore can be cast and moulded in various forms, ranging from extrusion into pipes through forming into thin-walled injection moulding (TWIM).

High crystalline polypropylene (HcPP) is physically stronger and more rigid than homopolymers due to its molecular structure, which provides a unique solution to specific customers’ needs for thickness of the PP product. HcPP is a downgauging (or thinner) product of homopolymers while maintaining all other properties including excellent resistance to chemical corrosion and heat. HcPP moulding is done by either extrusion or injection.

Random Copolymers (RACO) are derived through modification of the polypropylene chain by the addition of small comonomers. The modification results in improved optical properties.

RACO is more transparent with a clear appearance and excellent gloss, improved hot-sealing characteristics as well as improved physical impact, RACO PP resins show good chemical resistance including inorganic acidic, basic, and ionic, as well as to environmental stress cracks (ESCR).

Random Copolymers are commonly used as a skin layer in extrusion application for flexible packaging and in injection moulding for consumer goods due to their unique optical properties and excellent clarity.

Heterophasic Copolymers (HECO) are generated by polymerization of a rubber component within the polypropylene matrix polymer, leading to unique PP with extraordinary resistance to physical impact, especially at low temperatures. HECO can be applied in extremely harsh environment, from negative temperatures to very high temperatures such as from the refrigerator freezer to microwave. Because of its extraordinary resistance to high physical impact, HECO is widely used for the manufacture of vehicle bumpers, crates and pails, containers, and drainage pipes.

HECO is inherent with a broad range of melt flow rates (MFR) and can therefore be moulded by piping extrusion, blown film extrusion, or thin-walled injection (TWIM).

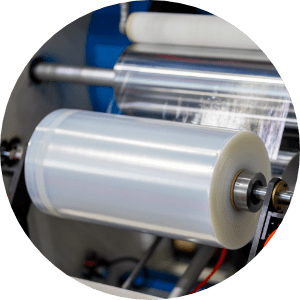

Terpolymers are derived from three monomers to create special PP with a uniquely high flexibility physical properties perfectly fit for a skin layers in flexible packaging, including CPP (cast polypropylene), BOPP (biaxially oriented polypropylene), and POF (polyolefin shrink film).

Terpolymers were developed as a breakthrough for the film industry with unique physical properties including sealability at low temperatures, technically termed low SIT (seal initiation temperatures), excellent optical properties with high transparency and high gloss, as well as excellent forming under high-speed processing machinery.

/ HMC Polymers

Trade Names

Moplen

Moplen represents a group of products with high quality and investment cost-effectiveness, together with continuous improvement to satisfy customers’ needs. Moplen consists of Homopolymer, Random Copolymers, and Heterophasic Copolymers.

Adstif

Adstif represents a group of products with higher rigidity and strength together with superior physical properties to conventional PP. Adstif consists of Homopolymers, Random Copolymers, and Heterophasic Copolymers. The stiffness of Adstif products helps our customers produce goods with reduced thickness, which translates into raw material and hence more cost savings.

Clyrell

Clyrell represents a group of products with much higher clarity and transparency as a result of the rearrangement of the PP molecular structure. Because of its extreme transparency and gloss, customers can find that Clyrell products are unique and have become a choice substitute for other raw materials like glasses and engineering polymers, such as polycarbonate.

Purell

Purell represents a group of products specifically suitable for the health & hygience industry, since they are uniquely produced with intensive quality processes and delivery according to international regulatory standards including US Pharmacopeia, European Pharmacopeia, and Drug Master File, supporting the use of the resins in medical and pharmaceutical applications.

Adsyl

Adsyl represents a group of products including Random Copolymers and Terpolymers with excellent sealable properties, specifically compatible with casting technologies of BOPP (biaxially oriented polypropylene), Double Bubble, Cast, and Blown film. Adsyl products are generally applied as coextrusion or coating film for being a skin layer with easy sealable function.

Hostalen PP

Hostalen PP represents a group of Copolymer products specifically suitable for pipe manufacturing such as high-pressure, hot-water, drainage, sewage, and injection-moulding piping. It is extraordinarily strong and rigid, capable of double-layer and large, complicated strand piping.