Physical Properties

HMC Polymers is fully committed to continuous research and development of catalysts, processes, and various innovations to ensure delivery of unique products to meet ever-changing needs of customers.

The physical properties and characteristics of PP are prime factors for uninterrupted and efficient production of the final moulded and casted products. We have provided full disclosure of fundamental PP product data of all grades to customers for their decision-making on procurement and applications as well as custom-made orders.

PP Molecular Structures

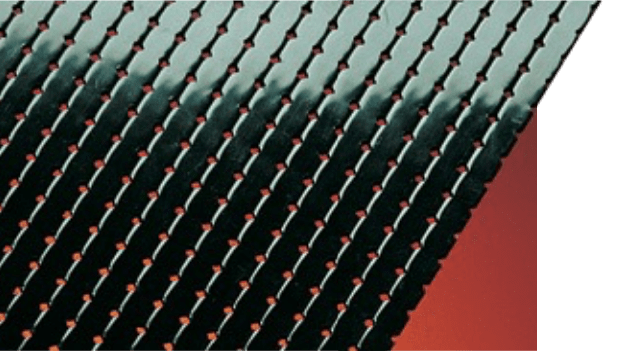

Molecular structures are the foremost parameters affecting the physical properties of PP. The molecular structure is semi-crystalline with some molecular chains bonded in a neat order like all other crystals, while the remaining ones are bonded in disorder, forming an amorphous structure.

PP is composed of three theoretical basic structures:

- Isotactic side group: all the molecules are located on the same side of the main polymer chain or the prime molecular chain.

- Syndiotactic side group: the molecules are located on the opposite side of the main polymer chain.

- Atactic side group: the molecules are scattered in locations.

General commercial PP is composed of two main molecular structures, isotactic and atactic, mostly with more than 90% isotactic.

PP Parameters

PP physical properties are controlled by the following key parameters.

PP can be classified into Homopolymers (HOMO), Heterophasic Copolymers (HECO), or Random Copolymers (RACO). The following table illustrates a comparison of their physical properties. Rigidity is the dominant property of Homopolymers, highest resistance to impacts is that of Heterophasic Copolymers, and transparency is that of Random Copolymers.

| Rigidity | Impact Strength | Transparency | |

|---|---|---|---|

| Homopolymers | 1 | 3 | 2 |

| Heterophasic Copolymers | 2 | 1 | 3 |

| Random Copolymers | 3 | 2 | 1 |

Remarks:

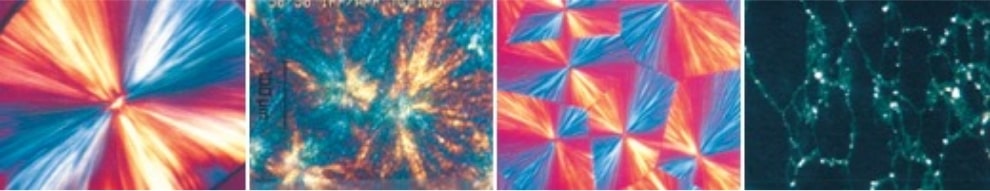

Heat induced in the moulding process and nucleating agents are the two major factors affecting the size and shape of PP crystallisation.

Crystal structure (left), nucleus growth pattern (middle), and rapid cooling of PP (right) during the cooling process.

During the rapid cooling of PP, numerous PP crystals form rapidly in all directions, thus squeezing the crystals.

Conversely, when the cooling process is slower, the PP crystals will become larger and brittle as well as fragile. Brittleness could also be developed during crystallisation when induced with shear stress, thus causing premature crystallisation.

By controlling the speed and temperature of crystallisation, physical properties can vary entirely. Crystallisation of the Adstif group is consistently controlled to be very refining, resulting in extreme stiffness, similar to High-impact polystyrene (HIPS) and certain PVC. In addition, the Adstif group products are highly heat-resistant, with a very shiny surface.

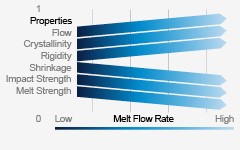

The melt flow rate (MFR) is dependent on the molecular mass of polymer, of which the size and length of the bond chain can be designed and controlled by polymerisation. MFR controls the pelletization and moulding processes. Higher MFRs determine higher flows in the moulding block, causing unique PP properties, especially increasing the hardness and the creepage, but lowering durability and impact resistance.

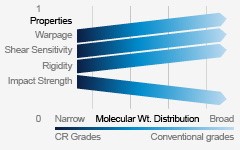

Ziegler-Natta PP is a PP with medium-high molecular mass distribution (MMD) during the production process. MMD, wide or narrow, dictates strengths and weaknesses of certain PP properties depend on the moulding process.

Our PP products are typically highly durable and highly resistant to chemical corrosion. Customers are advised to consult experts before PP selection, especially when applying the products under a chemical environment.

HMC Polymers provide a list of more than 260 types of chemicals and substances, referenced from ASTM D543.

Some polymers can develop cracks under certain chemical environment or under shear stress, particularly when exposed to soaps and detergents under high temperatures, thus reducing physical properties of some polymers, including polyethylene. However, PP products has a good stress cracking resistance

PP has high barrier properties to moisture and water than general plastic materials. However, its permeability is limited to gases such as oxygen and carbon dioxide, but adequately for application as containers for food preservation, including butter, yogurt, and cream.

The extent of gas permeability depends on the molecular mass. A small molecular mass results in higher permeability; a large molecular mass has limited permeability.

To ensure product acceptance by and satisfaction of customers, HMC Polymers values organoleptic properties and chemical additives of its PP products, particularly when used in food packaging with zero contamination and unwanted odors.

Notches significantly affect the impact strength of plastic products. PP products are, however, resistant to notches and therefore command higher impact strength.