PP Packaging Protects Contents

Introduction

The use of Polypropylene in food packaging is growing globally due to tangible benefits for the manufacturer and the consumer. These include light weight, delivering savings on packaging and transportation costs; hygienic protection of contents over the shelf life period; design freedom and manufacturing versatility; and convenience of use.

During the COVID-19 pandemic, customers have shown confidence in Polypropylene packaging to ensure food safety and hygiene.

Consumers are becoming increasingly aware of potential risks arising from food and certain packaging interactions. Several national and international organizations are updating food contact safety standards and making them more stringent. Food packaging companies are therefore implementing strict adherence to the regulatory requirements for food contact applications.

Food Safety

Regarding food safety, the effect of “Phthalates" has been long discussed for its adverse effect on the endocrine system. Phthalates used as plasticizers at high dosage levels found in flexible PVC applications such as toys, teethers and pacifiers, may be responsible for such medical problems.

In the case of Polypropylene manufacturing, phthalates are used as part of the catalyst systems and mostly consumed during the production process. Small residual contents of phthalates are less than the statutory limit of 0.1% (as defined by REACH compliance).

How do we know its safe?

How can consumers distinguish whether the plastic products they use contain any hazardous chemicals and are still within the officially specified control limit of such substances? The Regulatory Framework is the control mechanism that insures consumer safety and manages food contact materials, especially in the United states, Europe and Japan. These regulations strictly regulate the type and quantity of chemical substances in the food packaging. In addition, these governances block the trade of materials that are not in compliance.

Consulting the expert

HMC Polymers is pleased to discuss this important subject with Dr. Piyatida (Tung) Pukclai, an Asia-Pacific Business Development & Regulatory Policy Director of knoell,Thailand, one of the leading service providers for worldwide registration and regulatory compliance.

Dr. Pukclai has overview responsibility of all registrations and regulations including scientific data and the development of regulatory policy in Asian countries for Industrial Chemicals, Food Contact Materials, Biocides, and Crop Protections.

"Phthalates are widely used as plasticizers to make plastics flexible, particularly those made out of polyvinyl chloride (PVC) or vinyl plastic. Some of the common phthalates are found in consumer products.

The phthalates classified as harmful to reproduction and included in the Candidate List under REACH, are considered substances of concern to human health. It has been shown that phthalates have the potential to accumulate and magnify in terrestrial organisms and in the human body through multiple sources and pathways, and may lead to significant human health risks such as problems for the endocrine or reproductive systems, asthma and allergies.

The omnipresence of phthalates results in human exposure via multiple pathways such as oral, dermal and inhalation for prolonged periods.”

Phthalate bans are increasing

“Therefore, it may not come as a surprise that phthalates are strictly regulated in the European Union (EU) and other countries and the bans continue to mount against phthalates. The EU restricts several phthalates that are considered dangerous for human health under the REACH Regulation, the Toy Safety and RoHS Directives, the EU Food Contact Materials Framework Regulation and other regulations. The EU has banned BBP, DBP, DEHP, DIDP, DINP, and DNOP in toys and childcare articles since 1999.

The U.S. Consumer Product Safety Commission (CPSC) issued a rule prohibiting children's toys and child care articles from containing several specified phthalates. Furthermore, DBP and DEHP are banned in cosmetics sold in the EU. In Thailand, DBP, BBP, DMEP, and several more phthalates are prohibited for use in cosmetic products as the Minister of Public Health issues a Ministerial Regulation RE: List of substances which must not form part of the composition of cosmetic products B.E. 2559; likewise in Australia and New Zealand.

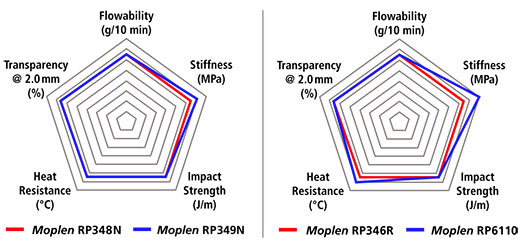

This trend, seen in the EU and the U.S., is becoming more prevalent in Asia. Besides regulation of this area, the trend is also due to more and more companies wanting to be at the forefront of a direction focusing on health and environment-friendly products. Today, there are several examples of successful replacement of phthalates by other less harmful substances in PP products such as HMC's Moplen RP349N and RP6110.

In addition, with the regulation of toys, food packaging and cosmetics it is now possible to manufacture those products without the use of phthalates or the phthalates of high concern. As a result, HMC manufacturing customers report business benefits as their products meet consumer demands.

HMC offers you solutions

Even though some of HMC’s polypropylene resins are produced using phthalate catalyst, the residue of such chemical is a truly small quantity at ppb level which Is significantly below the tolerable limit as referenced in the mentioned regulations.

To address the health and safety concerns of modern age consumers, HMC has taken a step forward to Introduce non phthalate catalyst based PP random copolymer grades for baby feeding bottles, food packaging and consumer/houseware applications.

Produced using 5th Generation catalyst, HMC random copolymer grades Moplen RP349N (11 MFI) and Moplen RP6110 (25 MFI) are able to offer the next level of stiffness and impact balance. Most importantly, brand owners can gain consumer confidence by offering non phthalate solutions.

For more details please click the links below:

Moplen RP349N

Developmental Grade Moplen RP6110

For additional information or sales enquiries please contact sales@hmcpolymers.com